Inspection Services

Remote and visual inspections

Furphy Inspection Services maintains a range of visual and remote visual inspection options to examine tank and vessel interiors. Our team capture high definition images of typical problems such as surface cracks, but can also assess other features such as agitators and spray balls. Remote inspection capability also offers a solution for areas that are difficult to access due to factors such as tank or vessel height, and can significantly reduce confined space entry requirements in many situations.

Available services include:

- Remote camera inspection

- Pipe and tube camera inspection

- Confined space inspection

- Penetrant inspection

Specialised repair

Building on our inspection, assessment and design capabilities is our specialist site repair team. This team can take inspection and assessment solutions and deliver them back into your assets. They are fully trained and licensed in high risk works such as confined space and scaffolding and can deliver results efficiently and safely. Our integrated inspection, assessment, design and repair capability makes Furphy Inspection Services unique in tank and vessel management.

Available services include:

- Internal and external scaffolded repair

- Confined space entry and repair

- General repair

Condition Assessment

Many customers have tanks or vessels with limited available maintenance records, whilst others may be uncertain of the condition of their assets.

Our team can undertake detailed assessments to a range of criteria that suit customer needs and applications. Our site team can not only assess and benchmark your tanks and vessels, but we can also package our site services with our design capabilities to optimise assets. We can undertake ultrasonic thickness testing, detailed dimensional and condition surveys, grade the materials of construction and review records. Our team understands the unique challenges that typify older tanks and vessels. We work with you at every stage to get the best possible result.

Available services include:

- Visual and remote inspection

- Survey and design assessment

- PMI (materials grading) using portable testing equipment

- Ultrasonic thickness testing

- Hydrostatic testing

- Document and records review and assessment

Design Engineering Assessment

Our team design tanks and vessels to many standards, both local and international. Now our service customers can take advantage of this and other specialised design capabilities. We can undertake fundamental design processes such as verification, but can also provide more complex solutions for existing tanks and vessels. Our design capability is supported by our site team, who can survey your existing assets and relay this information directly to our designers to deliver a complete solution for existing tanks and vessels.

Available services include:

- New tank and vessel design

- Existing tank and vessel assessment

- Design verification

- Drafting

- Finite Element Analysis (FEA)

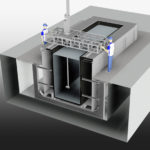

Kettle Inspection Device (KID)

Galvanizing kettles are a sizeable investment for any business, and come with a set of specialised risks that need to be managed. Furphy Inspection Services Kettle KID system can check your kettle thickness in one day without interrupting your production.

KID is a submersible ultrasonic probe that can accurately test the thickness of your kettle wall to provide an insight into thinning patterns and rates, heat shield integrity and threats such as dross corrosion.

Galvanizers across Australia and New Zealand are taking advantage of this technology to eliminate pump-out checking and build a history to optimise their kettle operations.

What once took days or weeks now takes hours.

Don’t continue with the unnecessary expense of pump-out kettle checks and the associated shortening of kettle life and production losses. Contact us today to discuss your needs.