Case Study: Pharmaceutical Pressure Vessels

Pharmaceutical Pressure Vessels featuring Unique Riboflavin CIP Testing

Client:

Hooker Cockram

Project:

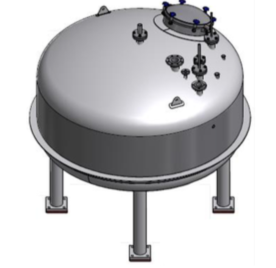

10,000L Waste Treatment Collection Tank (PC3) & 5,600L Animal Waste Collection Tank (PC2)

For the Elizabeth Macarthur Agricultural Institute Part of NSW Department of Primary Industries

Location:

Menangle, NSW

Project Specifications:

Two pharmaceutical waste treatment pressure vessels were specified with unique Riboflavin CIP (clean-in-place) testing to be carried out during tank manufacture, to meet the hygiene requirements of this project.

Design Considerations:

As these tanks are pressure vessels, structural engineering design was completed in house, in accordance with Australian Standard AS1210 : Pressure Vessels, to withstand the 300kPa positive pressure and full vacuum conditions that occur in the process. Designing in accordance with AS1210 also takes into consideration; Earthquake actions at the installation location (AS1170.4) and an (AS4343) Hazard Level “B”, due to the vessel contents, volume and pressure conditions.

Overall tank design also considered the working volume requirements of each vessel and height restrictions for the area of installation. PC3 is a 10,000L vessel with an overall height of 4,250mm and PC2 a 5,600L vessel with an overall height of 2,900mm.

Pressure relief mechanisms must be fitted to the vessels, to prevent failure caused by vacuum conditions or over-pressurisation within the vessel. Burst discs are used for this application due to their ‘leak tight’ properties. Burst discs are a single use safety mechanism; designed to rupture at the maximum design pressure of a vessel and must be replaced after bursting.

Design Considerations continued:

Clean-in-Place requirements are of a very high standard for these vessels. This project uses a hot CIP system that includes the use of steam and installation of three individual rotating spray heads in the top heads of each vessel. These rotating spray heads eliminate the effects of shadowing and ensure complete coverage of all internal surfaces.

Recirculation was specified for the design of these vessels. The product contained within each vessel needs to be turned over in the process and recirculation is a less vigorous form of moving product than agitation. It is also a simple and cost effective inclusion.

Riboflavin CIP Testing & Build Requirements:

Due to the pharmaceutical grade conditions, these vessels were required to have the Clean-In-Place (CIP) system tested during manufacture using Riboflavin Testing. The purpose of this test is to ensure that the effects of shadowing are eliminated during CIP and that all internal surfaces are cleaned. Shadows indicate areas that aren’t reached and are often within nozzles, manways, projections or areas that are obstructed by agitators or baffle plates. These areas must be cleaned.

This testing procedure involves coating the inside of each tank with a fluorescent dye prior to running the CIP system. Once CIP is complete, the internals of the tank are inspected under UV light. Any areas missed by the CIP are highlighted by the remaining fluorescent dye (shown right) that hasn’t been washed off. The system is then adjusted and retested until a complete interior clean is achieved.

Early results from Riboflavin heads rather than standard spray balls for a superior clean of all surfaces. CIP testing prior to adjustments

Each tank contains three CIP spray devices with individual, rotating spray

Tanks were fabricated at Furphy Engineering’s Shepparton plant in Victoria, using stainless steel sourced through Australian-based supply outlets. The 10,000 square metre manufacturing facility is ASSDA Accredited Quality Stainless Steel Fabricator with ISO9001 certification in management systems for superior quality assurance.

Further Inspections & Testing:

Following manufacture, pressure vessels are subjected to testing in accordance with AS1210. Pressure vessels undergo 100% visual scanning of weld seams to AS4037: 100% and are hydrostatically tested in accordance with AS4037, to 1.5 times the design pressure (450kPa for these tanks). Tanks were subjected to the CIP Riboflavin Tests to confirm the internal cleaning system met specifications and this was witnessed by the client, prior to delivery.

Contact out team on (03) 5832 1400 or via info@furphyengineering.com.au